The era of steam was dominated by steam locomotives and one question I get asked more than all the others is how does a steam locomotive work? In this not-so-romantic blog, I’ll explain it to you. (Without engineering jargon!)

In my experience, steam locomotives are one of those subjects that everyone makes out to be more complicated than it actually is. Those who try to explain it pride themselves on knowing all the complex parts and knowing exactly how many bolts it takes to hold a boiler together.

The biggest problem is that people use far too many big and complicated words. That is one thing I refuse to do. I hate using any big or fancy words, mostly because I don’t understand them myself.

Our lesson on how a steam locomotive works starts with a short and very simple sentence.

A steam locomotive is a large kettle on wheels

Obviously, if you were to put a kettle and a steam locomotive next to each other, you wouldn’t need me to tell you that there are a lot more parts on a steam locomotive than there are on a kettle.

But they both do pretty much the same thing. They boil water and exhaust steam. A kettle just lets the steam go; the steam locomotive uses the steam to move.

The two of them share a key ingredient. Water. Without water, neither a kettle nor a steam locomotive would serve any purpose.

Their other key ingredient is where the two differ. A kettle relies on electricity to boil its water whilst a steam locomotive requires coal.

Let’s update our sentence…

A steam locomotive is a large kettle on wheels. It’s made up of lots of different parts and has two main ingredients. Water and coal.

We now have the two main ingredients for our steam locomotive to work. But where was it all stored? This is where the Tender comes into its own.

The Tender is like a trailer on a car. It’s the bit you can see behind the bigger locomotives. If you happen to see a locomotive without a Tender, it could mean that it has been robbed. But, perhaps more likely, it probably means you’re looking at a tank engine.

Tank engines are much smaller and would mostly pull carriages on smaller railway tracks and in the shunting yards. This meant they didn’t need as much coal and water as the bigger locomotives which did the longer journeys.

The Tender is split horizontally in half. The top half is reserved for coal. Some of the biggest locomotives carried 10 tonnes of coal in the Tender.

The bottom half is for water. Water is possibly the most important ingredient for a steam locomotive.

Water to a steam locomotive is like Mickey Mouse to Minnie Mouse, trumps to laughter, Marmite to toast, sprouts to my belly, bogies to noses, poo to toilets – Sorry I got carried away.

Water is really important to a steam locomotive.

Without water, there wouldn’t be any steam and if there’s no steam then a steam locomotive goes nowhere. But all joking aside- if a steam locomotive ran out of water whilst the locomotive was hot there is a really big chance it would explode.

Between 2 and 4 thousand gallons of water could be stored in the Tender. Four thousand gallons is enough to fill sixty average-sized bathtubs.

Sorry to move away from steam locomotives, but I don’t know how big an average bathtub is. All I really know is that I’ve never been in a bath I can fit comfortably in. I’m 6ft 4” so I don’t fit in anything comfortably really. I challenge you to find out how big an average bathtub is!

Anyway. Count the number of baths you have from now on and when you get to 60 you’ve used a Tender’s worth of water.

Four thousand gallons of water sounds like a lot but in reality, it would disappear really quickly. But why did water disappear so quickly? My bad joke answer is that they hadn’t invented plugs yet. The correct answer is that steam locomotives were thirsty beasts.

So thirsty that four thousand gallons would be gone in a few short hours. All hours, of course, are the same length- but saying a few short hours sounds more dramatic- if it bothers you then you can rewrite the sentence to say “a few regular-length hours”. Your call.

I think it’s time for an explanation update.

A steam locomotive is a large kettle on wheels. It’s made up of lots of different parts and has two main ingredients, water and coal. The water and coal is stored at the back of the locomotive in what is called the tender.

Do you think the coal and water remained in the Tender for the whole journey? If you said yes, then you’re in for a surprise!

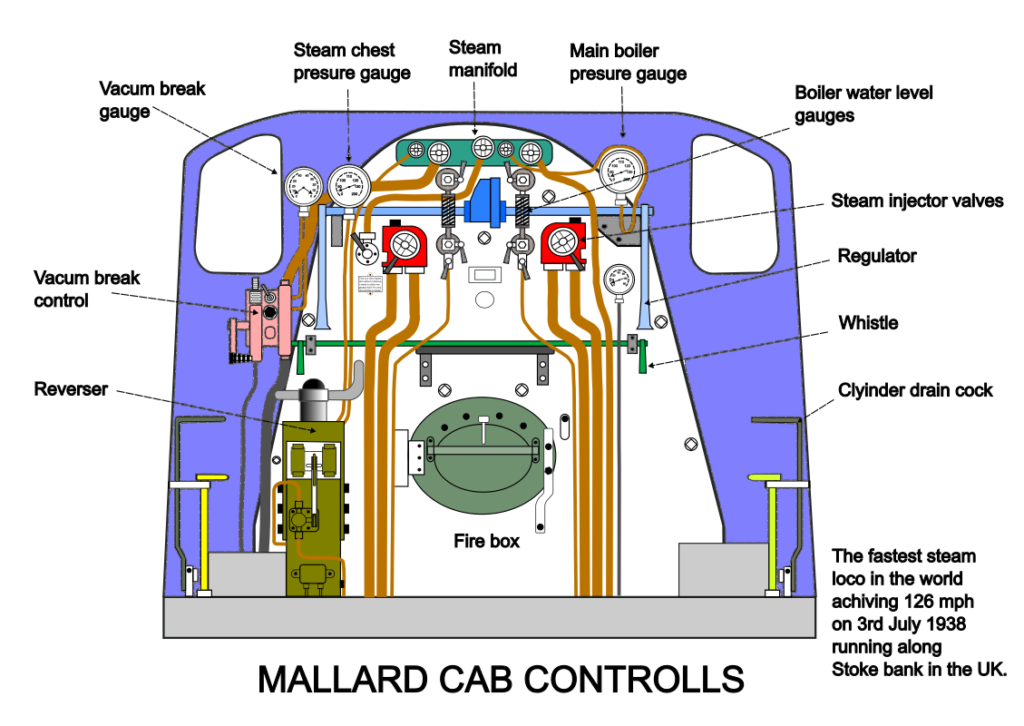

In front of the Tender is the cab. Inside the cab is the footplate. And on the footplate is where the driver and fireman work.

If you’ve seen a steam locomotive before you will already know cabs have a roof to keep the crew protected from inclement weather. -Rain, snow, bogies etc.

Believe it or not, cabs didn’t always have roofs. On early steam locomotives cabs didn’t even have sides. And seats weren’t really introduced until the mid-1800s. Early railway companies were afraid that their crews wouldn’t work hard enough or even fall asleep if they were too comfortable. I’m fairly confident that even the heaviest of sleepers wouldn’t have been able to sleep in the cab of a steam locomotive.

7 reasons why you shouldn’t take a nap in a steam locomotive cab!

- The noise! Controls are hissing, coal in the Tender is wobbling, the wheels make the annoying clickety-clack sound and there’s a lot of clanging metal.

- The heat! It’s really hot, the fire reached a sweaty 1500 degrees!

- The weather! Rain will make it feel like you’re taking a nap in the shower (please don’t do that)

- Bumpy ride! Imagine a bouncy castle made out of wood and metal that always has that annoying kid who never stops bouncing inside it.

- Falling off the engine! I already mentioned that early locomotives didn’t have sides on the cabs. It wouldn’t take much for you to fall out. Not only would it be incredibly embarrassing I’m sure it would hurt as well.

- Accidentally being thrown in the fire! I already said the fire can be 1500 degrees- even people who like hot showers wouldn’t like being thrown in the fire.

- Bird poo danger! Granted this is a danger whenever we step outside but imagine being asleep with your mouth open when a bird poops overhead. And you thought your regular morning breath was gross.

So, what exactly is it that the driver and fireman do?

The driver is in charge of three main controls.

- The regulator

- The reverser

- The brakes

I’ll write them again so we can all understand them.

- The accelerator

- Pretty much gears

- The brakes

In fact, let’s make it even simpler.

- The thing that makes you go faster.

- Decides if you’ll move forward or backwards.

- The brakes.

The fireman’s main job is to shovel coal into the firebox. I bet you can’t guess what’s inside the firebox. I’ll be honest, it took me five years to work it out.

Fire is inside the firebox.

In order to keep the fire going the fireman would have to shovel pretty much non-stop. Rather them than me I say!

Whoop whoop- explanation update time.

A steam locomotive is a large kettle on wheels. It is made up of lots of different parts and has two main ingredients, water and coal. The coal and water are stored at the back of the locomotive in what is called the tender. In the cab, the driver controls the locomotive whilst the fireman shovels coal into the firebox.

But why does a steam locomotive need a fire in the first place? It’s obvious, isn’t it? To make the best marshmallows in the world.

I mean, to make hot hair -air!

The fire makes hot air which travels through long tubes in the boiler where the water is. It then pops out the chimney like an invisible, and far less interesting, jack-in-the-box. As the hot air travels through the boiler, it boils the water like a giant kettle- I did tell you at the start of this section that steam locomotives were like kettles.

I know it’s not been very long but let’s update our explanation again. I just like putting things in bold- makes me feel important.

A steam locomotive is a large kettle on wheels. It is made up of lots of different parts and has two main ingredients, water and coal. The coal and water are stored at the back of the locomotive in what is called the tender. In the cab, the driver controls the locomotive whilst the fireman shovels coal into the firebox. The fire makes hot air which travels through long tubes in the boiler. The water around the pipes boils into steam.

Ho-Ho- Ho! Merry… hang on, I’m not Father Christmas…

So, we now have steam which is good as we’re explaining how a steam locomotive works.

The steam rises to the top of the boiler and gives the driver a reading of steam pressure. Steam pressure is a steam locomotive’s best friend but can also be its worst enemy. Not enough steam pressure and you don’t go anywhere, but too much steam pressure and the locomotive could explode. There’s a dial back in the cab which measures how much steam pressure there is.

Boiler explosions were more common than a lot of people realise. And they were certainly incredibly dangerous with the potential to cause untold damage. If a boiler exploded several hundred flaming hot bolts would fire out like bullets in every direction.

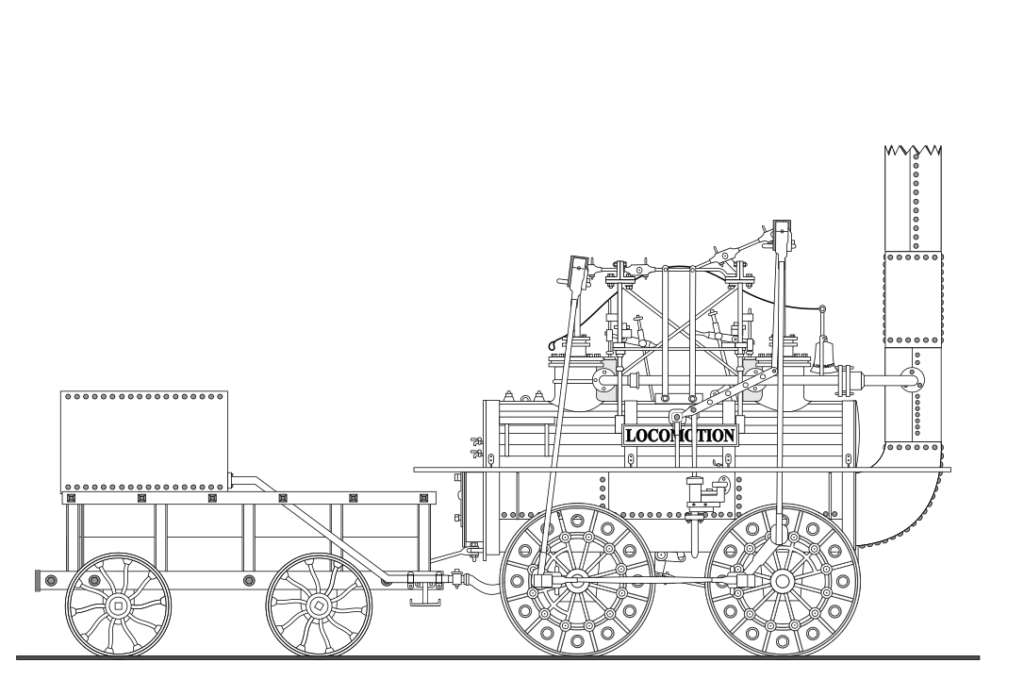

Jon Cree was hired to drive the steam locomotives on the newly opened Stockton and Darlington railway. When he was refilling the locomotive Locomotion No. 1 with water he made the decision to tie down the safety valve.

Safety valves were installed in the boiler and originally used weights. When the steam pressure got too powerful the steam would lift up the weights which would make the valve open and get rid of the steam pressure.

John Cree thought his experience would mean he knew, by listening to the boiling water, when he had enough steam pressure and there would be no danger of the locomotive gaining too much-I bet he didn’t believe in instruction manuals either. Because this is the unromantic railways you have probably already guessed he wasn’t as good at judging boiling water as he thought he was.

On hearing the hissing of impending doom from the boiler Cree made a desperate attempt to untie the safety valve to release the pressure but to no avail. The boiler of Locomotion No. 1 exploded. Cree survived for two more days but did pay the ultimate price for his mistake when he died.

Locomotion No. 1 was rebuilt after this incident and ended up running until 1841.

After that pleasant story let’s get back to how a steam locomotive works.

The steam rises upwards into the steam dome. The steam dome is the large lump that looks like a dome on top of the locomotive’s boiler. Once the pressure has built up, the regulator (the locomotives accelerator) comes into play.

When the driver moves the regulator, it lets steam from the steam dome into a pipe imaginatively named the main steam pipe.

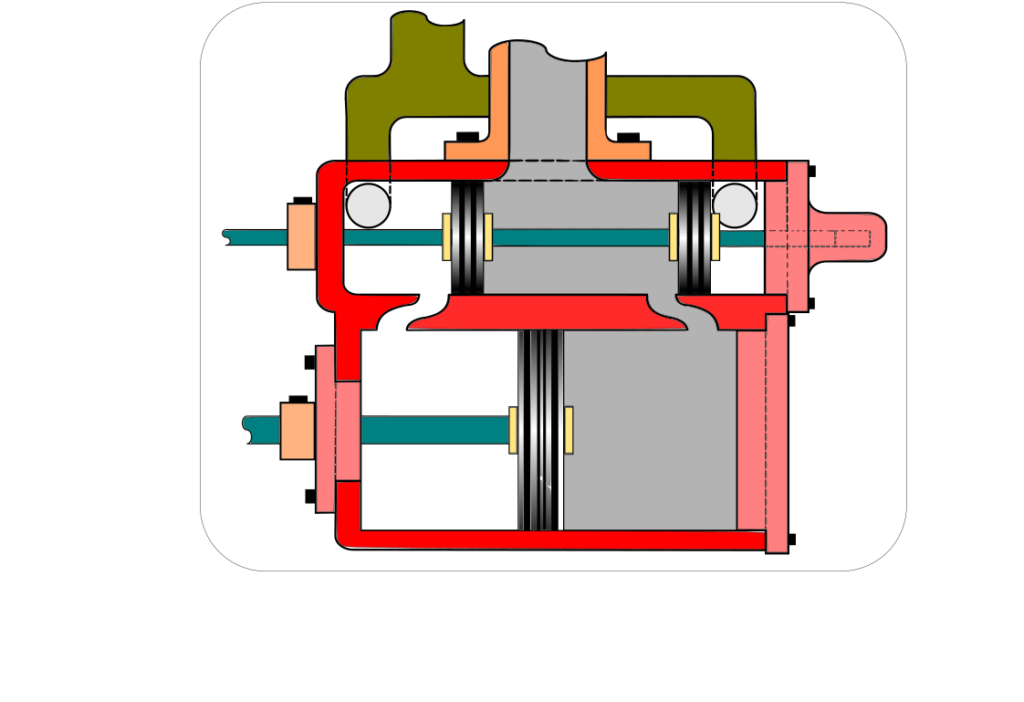

This pipe snakes down through the locomotive and into the cylinders. The cylinders are the metal box-looking things near the locomotive’s front wheels. These front wheels are called bogies- no word of a lie.

The steam pushes the pistons forward and backwards and the pistons moving forward and backwards is what makes the wheels turn around.

When the piston has moved forward and backwards the wheels will have spun around once. There are at least two pistons on a steam locomotive. One on each side and occasionally one in the centre.

Once the steam has pushed the piston it’s allowed to drift upwards through another pipe and out of the chimney. Let’s take a look at our final explanation of how a steam locomotive works.

A steam locomotive is a large kettle on wheels. It is made up of lots of different parts and has two main ingredients, water and coal. The coal and water are stored at the back of the locomotive in what is called the tender. In the cab, the driver controls the locomotive whilst the fireman shovels coal into the firebox. The fire makes hot air which travels through long tubes in the boiler. The water around the pipes boils into steam.

The steam rises to the top of the boiler and gathers in the steam dome. The driver opens the regulator which allows the steam to travel through the main steam pipe and into the pistons. The steam pushes the piston forward and backwards to move the wheels around. Once the steam has pushed the piston it travels back up through the locomotive and out of the chimney.

And that… is how a steam locomotive works. Do you see how simple it is when you get rid of all the complicated words? I hereby declare that from this point forward no complicated words shall ever be used again!

You’ve learnt a lot in this blog so go and take a break and get yourself a banana or something.

what to read next

This was taken from my book The Not-so-romantic Railways, which is available to buy on Amazon right now! So if you like the railways I’d recommend reading that next.

But, if you were looking for another blog to read, then here are some along a similar theme.